Stainless steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's resistance to corrosion results from the chromium, which forms a passive film that can protect the material and self-heal in the presence of oxygen.

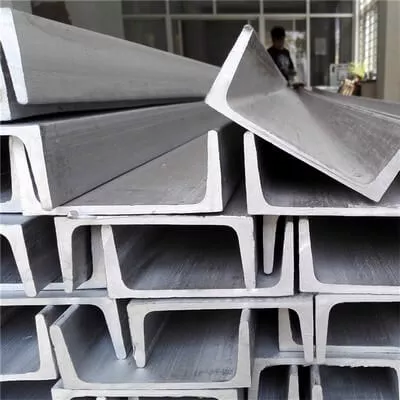

The alloy's properties, such as luster and resistance to corrosion, are useful in many applications. Stainless steel can be rolled into sheets, plates, bars, wire, and tubing. These can be used in cookware, cutlery, surgical instruments, major appliances, vehicles, construction material in large buildings, industrial equipment (e.g., in paper mills, chemical plants, water treatment), and storage tanks and tankers for chemicals and food products.

The biological cleanability of stainless steel is superior to both aluminium and copper, and comparable to glass. Its cleanability, strength, and corrosion resistance have prompted the use of stainless steel in pharmaceutical and food processing plants.

Different types of stainless steel are labeled with an AISI three-digit number.[4] The ISO 15510 standard lists the chemical compositions of stainless steels of the specifications in existing ISO, ASTM, EN, JIS, and GB standards in a useful interchange table.

Stainless steel material

200 series: Chrome-Manganese-Nickel

201,202, etc. : Manganese instead of nickel, poor corrosion resistance, widely used as a cheap substitute for 300 series in China

300 series: Chrome-nickel austenitic stainless steel

301: Good ductility, used for molding products. It can also be machined to harden rapidly. Good weldability. The wear resistance and fatigue strength is better than 304 stainless steel.

302: Corrosion resistance is the same as 304, because the carbon content is relatively higher and thus better strength.

303: By adding a small amount of sulfur and phosphorus to make it easier to cut than 304.

304: universal model; 18/8 stainless steel. Products such as: corrosion resistant containers, tableware, furniture, railings, medical equipment. The standard ingredient is 18 % chromium and 8 % nickel. Stainless steel that is not magnetic and cannot be changed by heat treatment. The GB brand is 06Cr19Ni10.

304 L: Same characteristics as 304, but low carbon so more corrosion resistance, easy heat treatment, but poor mechanical suitable for welding and not easy heat treatment products.

304 N: With the same characteristics as 304, is a nitrogenous stainless steel, nitrogen is added to improve the strength of the steel.

309: compared with 304 has better temperature resistance, temperature resistance up to 980℃.

309S: With a large amount of chromium, nickel, so good heat resistance, oxidation resistance, products such as: heat exchanger, boiler components, jet engine.

310: Excellent high temperature oxidation resistance, the highest use temperature 1200℃.

316: The second most widely used steel after 304, mainly used in the food industry, watches and ornaments, pharmaceutical industry and surgical equipment, molybdenum is added to give it a special structure resistant to corrosion. Because of its better resistance to chloride corrosion than 304, it is also used as "Marine steel".

316 L: Low carbon so more corrosion resistance, easy heat treatment, products such as: chemical processing equipment, nuclear power generators, refrigerant storage tank.

321: Similar to 304 in other properties except that titanium is added to reduce the risk of corrosion in the material weld.

347: Add stabilizing element niobium, suitable for welding aviation equipment parts and chemical equipment.

400 Series: Ferritic and martensitic stainless steel, manganese free, can replace 304 stainless steel to some extent

408: Good heat resistance, weak corrosion resistance, 11% Cr, 8% Ni.

409: Cheapest model (British or American), usually used as an automobile exhaust pipe. It is ferritic stainless steel (chromium steel).

410: martensite (high strength chromium steel), good wear resistance, poor corrosion resistance.

416: The addition of sulfur improves the processing property of the material.

420: "cutting edge grade" martensitic steel, similar to Brinell high chromium steel, the earliest stainless steel. Also used in surgical knives, can be made very bright.

430: Ferritic stainless steel, for decorative purposes, such as automobile ornaments. Good formability, but poor temperature resistance and corrosion resistance.

440: High strength cutting tool steel, slightly higher carbon content, after appropriate heat treatment can obtain high yield strength, hardness can reach 58HRC, belongs to the hardest stainless steel. The most common example is the "razor blade". There are three common models: 440A, 440B, 440C, and 440F (easy to process).

Series 500: Heat resistant chrome alloy steel.

Series 600: Martensitic precipitated hardened stainless steel.

Stainless steel speciality

1、weldability

Different uses of products have different requirements for welding performance. A class of tableware welding performance generally do not do requirements, even including part of the pot enterprises. But the vast majority of products need raw materials with good welding performance, such as second-class tableware, thermos cup, steel pipe, water heater, water dispenser and so on.

2、Corrosion resistance

The vast majority of stainless steel products require good corrosion resistance, like one or two types of tableware, kitchenware, water heater, water dispenser, etc., some foreign businessmen also do corrosion resistance tests on products: with NACL solution heated to boiling, after a period of time to dump the solution, wash and dry, said weight loss, to determine the degree of corrosion (note: When polishing the product, the emery cloth or sandpaper contains Fe components, which will lead to rust spots on the surface of the test.

3、Polishing property

stainless steel products are generally polished in the production of this process, only a few products such as water heaters, water dispensers and so on do not need polishing. Therefore, this requires the material polishing performance is very good. The main factors affecting polishing properties are as follows:

① Surface defects of raw materials. Such as scratches, pitting, pickling, etc.

② The problem of raw materials. The hardness is too low, it is not easy to polish when polishing (BQ is not good), and the hardness is too low, the surface is easy to appear orange peel phenomenon when deep stretching, thus affecting the BQ property. High hardness BQ sex is relatively good.

4、Heat resistance

Heat resistance refers to the high temperature stainless steel can still maintain its excellent physical and mechanical properties.

5、Carbon influence:

Carbon is an element in austenitic stainless steel that strongly forms and stabilizes austenite and enlarges the austenitic region. The capacity of carbon to form austenite is about 30 times that of nickel. Carbon is a kind of interstitial element, which can be improved significantly by solution strengthening

Stainless steel chemical composition

| Chemical Material Composition of SS 202 | ||||||||||

| Grade | Mn | C | P | Si | Cr | S | Ni | Mo | N | |

| Stainless Steel 202 | minimum | – | – | – | – | 17 | – | 4 | – | – |

| maximum | ≤7.5~10.0 | 0.15 | 0.06 | 1 | 19 | 0.03 | 6 | 0.25 | ||

Stainless steel mechanical property

| Mechanical Properties | ||||

| Grade | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Rockwell Hardness | Elongation at Break (%) |

| SUS202 | ≥275 | ≥520 | HRB≤95 | 55-60 |

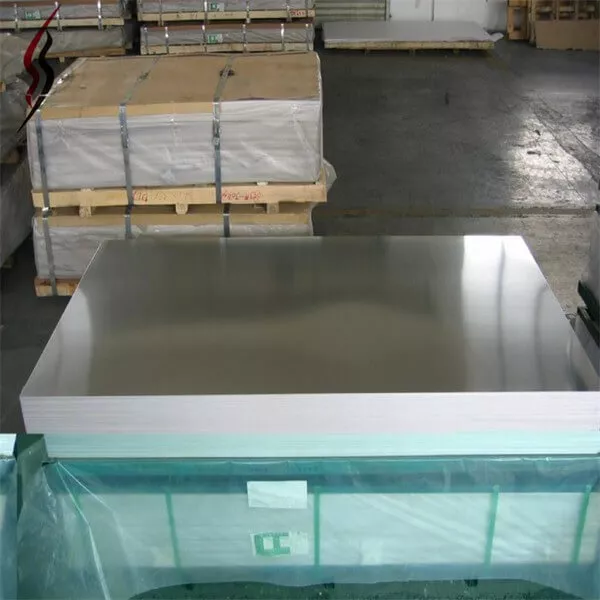

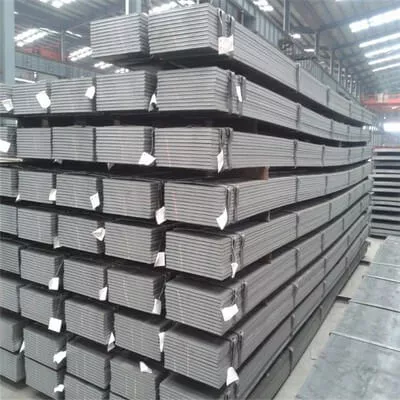

Stainless steel Specification

| Item | Stainless steel plate,stainless steel sheet (Hot rolled,cold rolled), |

| Stainless Steel Sheet/Stainless Steel Plate, | |

| 201 304 316 430 409 316L Stainless Steel Sheet/Stainless Steel Plate,stainless steel sheet price | |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

| Material | 310S,310,309,309S,316,316L,316Ti,317,317L,321,321H,347,347H,304,304L, |

| 302,301,201,202,403,405,409,409L,410,410S,420,430,631,904L,Duplex,etc | |

| Surface | 2B,2D,BA,NO.1,NO.4,NO.8,8K,mirror,checkered,embossed,hair line,sand blast,Brush,etching,etc |

| Thickness | 0.01~200mm |

| Width | 3mm-2500mm or as required |

| Package | Standard export package,suit for all kinds of transport,or as required. |

| MOQ | 1Ton |

| Application | Construction Field/Ships/Building/Medical equipment/Food industry/ Table-wares/Construction/Kitchen utensils/Chemical industry |

View More

| stainless steel square rod manufacturer | stainless steel round rods |

| stainless steel square rod manufacturers | stainless steel smooth rods |

| stainless steel square rod supplier | stainless steel smooth rods 8 mm |

| stainless steel square rod suppliers | stainless steel smooth rods 8mm |

| stainless steel square rods | stainless steel square bar rod |

| stainless steel square stock rod | stainless steel square rod 5 16 |

| stainless steel stick rods 309l 1 8 | stainless steel square rod factories |

| stainless steel stir rods | stainless steel square rod factory |

Application

Our steel products are mainly used in chemical industry, petrochemical industry, offshore, seawater pipeline, desalination plant, nuclear engineering, paper and pulp industry.

Stainless steel outlet

We are a well known worldwide supply and export Stainless steel in following countries:,Italy, Philippines, France,Ireland, Portugal, Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Libya, Romania, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Ghana, Slovakia, Germany, Saudi Arabia, Afghanistan, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece, Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus, Finland, Gabon, Iran, Canada, Argentina, Lebanon.

津ICP备14003658号-55

津ICP备14003658号-55