Nickel alloy

Nickel alloys are used extensively because of their corrosion resistance, high temperature strength and their special magnetic and thermal expansion properties. The major alloy types that are used are: Iron-Nickel-Chromium alloys. Stainless Steels. Copper-Nickel alloys and Nickel-Copper alloys.

Nickel will alloy readily with many other metals, including chromium, iron, molybdenum and copper. This allows for a wide variety of alloys that demonstrate outstanding resistance to corrosion and high-temperature scaling, exceptional high-temperature strength and other unique properties, such as shape memory and low coefficient of expansion.

Nickel alloy application

1. Heat treatment industry. Such as furnace roller, bell furnace and annealing furnace.

2. Calciner. For example, it is used to calcination to produce high-performance corundum, calcination of chromite to produce ferrochrome alloy, and recovery of nickel used as catalyst in petrochemical industry.

3. Chemicals and petrochemicals for the preparation of new steam cracking crude gasoline furnaces for the production of hydrogen, etc.

4. Automatic device. Such as catalytic support systems, spark plugs.

5. Cleaning equipment for the nuclear industry, such as nuclear waste removal.

6. The steel industry. Such as direct reduced iron ore process, the production of titanium sponge

Nickel alloy classification

1、nickel-base superalloy.It has high strength, oxidation resistance and gas corrosion resistance at 650 ~ 1000℃. It is the most widely used alloy with the highest high temperature strength. It is used in the manufacture of aircraft engine blades and high-temperature components for rocket engines, nuclear reactors and energy conversion equipment.

2、ni-base corrosion resistant alloy.Resistant to all kinds of acid and stress corrosion.In addition to wear resistance, its oxidation resistance, corrosion resistance, welding performance is good. It can make wear-resistant parts and can also be used as cladding material, which can be coated on the surface of other substrate materials by surfacing and spraying process.

3、Nickel-based wear resistant alloy.In addition to wear resistance, its oxidation resistance, corrosion resistance, welding performance is good. It can make wear-resistant parts and can also be used as cladding material, which can be coated on the surface of other substrate materials by surfacing and spraying process.

4、Nickel-based precision alloy.With high resistivity, low resistivity temperature coefficient and good corrosion resistance, used for making resistors. Nickel base electric heating alloy is 20% nickel alloy containing chromium, has good oxidation resistance, corrosion resistance, can be used for a long time at 1000 ~ 1100℃ temperature.

5、Nickel-based shape memory alloy.It is widely used in the manufacture of automatic opening structures for spacecraft, self-stimulating fasteners for aerospace industry, artificial heart motors for biomedical applications, etc.

Nickel alloy chemical composition

| Grade | UNS Designation A | Carbon | Manganese | Phosphorus, max | Sulfur, max | Silicon | Chromium | Molybdenum | Others |

| P5 | K41545 | 0.15 max | 0.30–0.60 | 0.025 | 0.025 | 0.50 max | 4.00-6.00 | 0.44–0.65 | -- |

Nickel alloy mechanical property

| Mechanical properties of ASTM A335 Gr. P5 Pipes | ||||||

| Grade | Tensile strength, min: | Yield strength, min: | Elongation Requirements | |||

| KSI | MPa | KSI | MPa | Longitudinal | Transverse | |

| P5 | 60 | 415 | 30 | 205 | 30 | 20 |

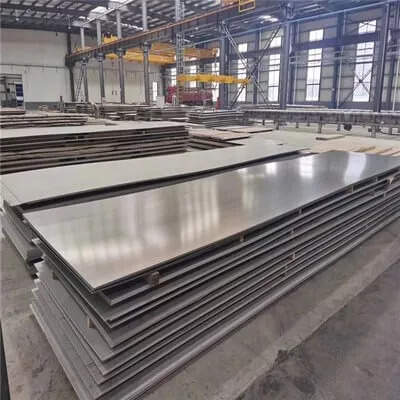

Nickel alloy Product Specification

Prdouct Name | Nickel Alloy Sheet |

Grade | Hastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N; |

Thickness | 0.8-36mm |

Width | 650-2000mm |

Length | 0.8-6 m or Customized |

Application | Auto, turbines, blades, powder and engines,etc |

Feature | High corrosion resistance, low density, good thermal stability |

Surface | Bright, Polished, Pickling, Acid cleaning, Sandblasting |

Quality and test | Hardness test, Bending test, Hydrostatic etc. |

Surface | Polished |

Trade Term | FOB CIF EXW ,etc |

Payment | L/C,T/T,Western Union,MoneyGram |

Delivery | 7-25days or according to the product |

Browse more

| wholesale Nickel alloy factory | wholesale Nickel alloy wire |

| wholesale Nickel alloy factories | wholesale Nickel alloy tube |

| wholesale Nickel alloy wire | wholesale Nickel alloy strip factory |

| wholesale Nickel alloy tube | wholesale Nickel alloy strip |

| Nickel alloy chemical composition | wholesale Nickel alloy sheet |

| Nickel alloy composition | wholesale Nickel alloy plate |

| Nickel alloy plate chemical composition | wholesale Nickel alloy pipe |

| Nickel alloy properties | wholesale Nickel alloy bar |

Application

Our steel products are mainly used in chemical industry, petrochemical industry, offshore, seawater pipeline, desalination plant, nuclear engineering, paper and pulp industry.

Nickel alloy outlet

We are a well known worldwide supply and export Nickel alloy in following countries:,Italy, Philippines, France,Ireland, Portugal, Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Libya, Romania, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Ghana, Slovakia, Germany, Saudi Arabia, Afghanistan, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece, Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus, Finland, Gabon, Iran, Canada, Argentina, Lebanon.

津ICP备14003658号-55

津ICP备14003658号-55