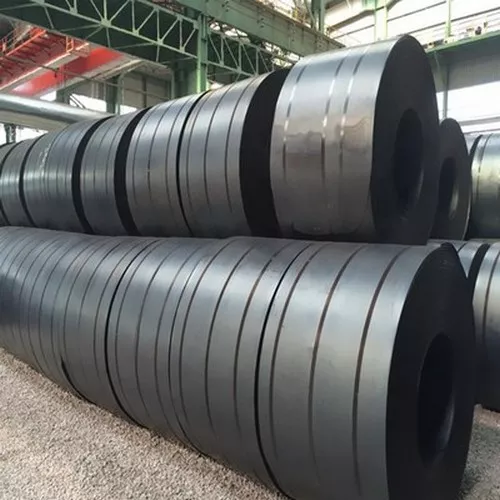

Cold Rolled Coil(CRC) description

It is often used in the steel industry and is distinguished from hot-rolled coils. It refers to the steel strip directly rolled into a certain thickness by a roll and rolled into a whole coil by a winder at normal temperature. Compared with hot rolled coil, the surface of cold rolled coil is bright and high finish, but it will produce more internal stress, and it is often annealed after cold rolling.

Cold Rolled Coil(CRC) advantage

Due to the absence of heating in the production process, there are no defects such as pitting and oxide sheet that often occur in hot rolling, and the surface quality is good and the finish is high. Moreover, the dimensional accuracy of cold-rolled products is high, and the performance and organization of products can meet some special requirements, such as electromagnetic properties and deep drawing properties.

Cold Rolled Coil(CRC) specification

| Product Name | Cold Rolled Carbon Steel Coil |

| Technology | Cold rolled |

| Grade | SPCC, SPCD, SPCE, SPCEN, DC01, DC02, DC03, DC04, DC05, ST12-ST14 |

| Thickness | 0.12-3mm |

| Width | 30-1250mm |

| Certificate | CE,ISO |

| Terms of payment | T/T,L/C at sight.etc. |

| Standard | GB/T5213-2008, JIS G3140-2550, EN10130-2006, DIN1623 |

| Application | Safety Door/Handware/Accessory/Metal Drum and so on |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Place of Origin | China |

Hot sale products

| arbon steel coil nails factories | carbon steel coil price |

| carbon steel coil nails | are coil springs high carbon steel |

| carbon steel coil manufacturers in china | carbon coil steel differences between heats in progressive die |

| carbon steel coil manufacturers | carbon steel coil manufacturers india |

| carbon steel coil manufacturer | carbon steel coil nails pricelist |

| carbon steel coil in stock | carbon steel coil pricelist |

津ICP备14003658号-55

津ICP备14003658号-55