410 Brushed Stainless Steel Pipe description

Used as engineering steel, the SA 268 Tp 410 is a base martensitic grade of stainless steel. The UNS S41000 or Stainless Steel Type 410 Erw Tubing like most alloys in the martensitic category can be hardened or tempered using heat processing. Any heat treatment process performed on the Stainless Steel Aisi 410 Square Tubing enhances its mechanical properties, specifically its hardness properties.

410 Brushed Stainless Steel Pipe advantage

corrosion resistance properties of the Stainless Steel Grade 410 Round Tubing is lower in comparison to austenitic stainless steel grades. This being said, martensitic grades such as SS 410 Seamless Tubes are taken into consideration for those applications where good hardness property is a primary requirement. Since the Sa-268 Tp 410 Material has magnetic properties and is able to retain this property even when they are in an annealed or heat treated condition. Hence ASTM A268 Tp 410 could work well in applications that require magnetism. SA 268 410 SS Tubing in continuous service resists oxidation up to 1292°F and in intermittent service, the A 268 Tp 410 Welded Tubes can be used up to 1500°F. To sum up, the main characteristics of 410 Stainless Steel Tubing includes high tensile strength along with low fracture resistance and low ductility as well.

410 Brushed Stainless Steel Pipe specification

Stainless Steel Pipe / Tube | |

Product Standards | Food Grade Sanitary Tube: JIS G3447, KS D 3585, ASTM A270, EN 10357(DIN 11850), AS 1528.1, ISO 2037(NF A49-249) |

Heat exchanger tube: ASTM A249 / ASME SA249, GB / T 24593-2009, HG 20537.2 | |

Industrial pipe: ASTM A312, EN 10217-7, GB / T 12771-2008, HG 20537.3 | |

Drinking water tube: GB / T 19228 | |

Mechanical tube: ASTM A554, EN 10296-2 | |

Materials (ASTM) | 201, 202, 301, 304, 304L, 304N, XM21, 304LN, 305, 309S, 310S, 316, 316Ti, 316L, 316N, 316LN, 317, 317L, 321, 347, 329, 405, 409, 430, 434, 444, 403, 410, 420, 440A, etc. |

Materials (EN) | 1.4372, 1.4373, 1.4319, 1.4301, 1.4306, 1.4315, 1.4303, 1.4833, 1.4845, 1.4401, 1.4571, 1.4404, 1.4429, 1.4438, 1.4541, 1.4550, 1.4477, 1.4462, 1.4002, 1.4512, 1.4016, 1.4113, 1.4509, 1.4521, 1.4006, 1.4021, 1.4028, etc. |

Materials (JIS) | SUS201, SUS202, SUS301, SUS304, SUS304L, SUS304N1, SUS304N2, SUS304LN, SUS305, SUS309S, SUS310S, SUS316, SUS316L, SUS316TI, SUS316N, SUS316LN, SUS316J1, SUS316J1L, SUS317, SUS317L, SUS321, SUS347, SUS329J1, SUS329J3L, SUS405, SUH409, SUS410L, SUS430, SUS434, SUS444, SUS403, SUS410, SUS420J1, SUS420J2, SUS440A, SUS440B, SUS440C, etc. |

Production Size | Outer Diameter Range: 6mm-2500mm (3/8"-100") |

Shape sections of tube | Round / Square / Rectangular/ Oval |

Usage of tube | Sanitary tubing: for food processing industry, beverage industry, sugar mill and so on; |

Surface | Polishing,annealing,pickling,bright |

Type | Hot Rolled and Cold Rolled,Welded, Decorative |

Quality Control | Mill Test Certification is supplied with shipment, Third Part Inspection is acceptable. |

410 Brushed Stainless Steel Pipe chemical composition

| C | Mn | Si | P | S | Cr | Ni |

| 0.15 | 1.0 | 1.0 | 0.04 | 0.03 | 11.5-13.5 | 0.5 |

410 Brushed Stainless Steel Pipe mechanical properties

| Tensile Strength MPa (min) | Yield Strength 0.2% MPa(min) | Elongation % | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

| 450 | 205 | 20 | 217 | 96 |

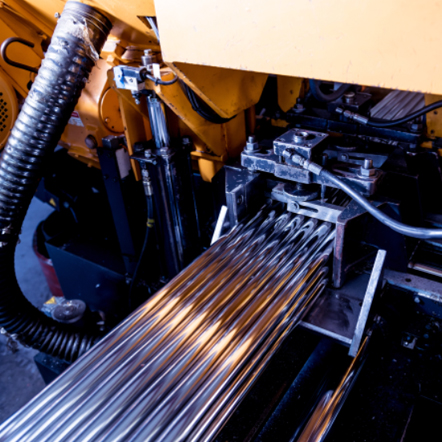

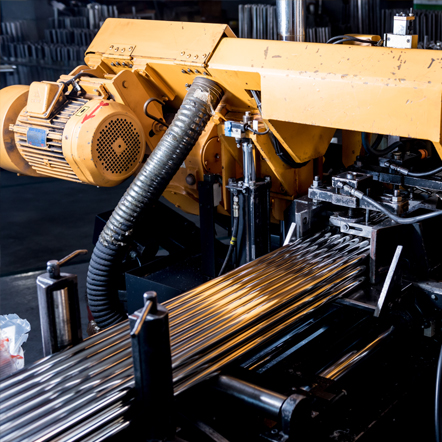

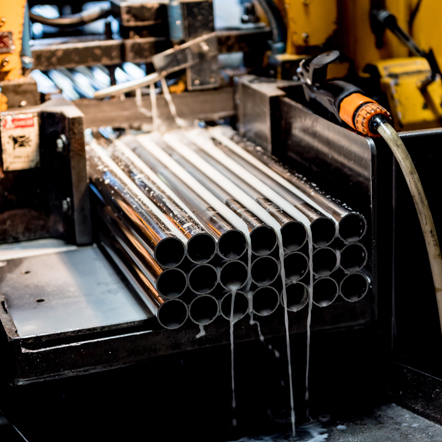

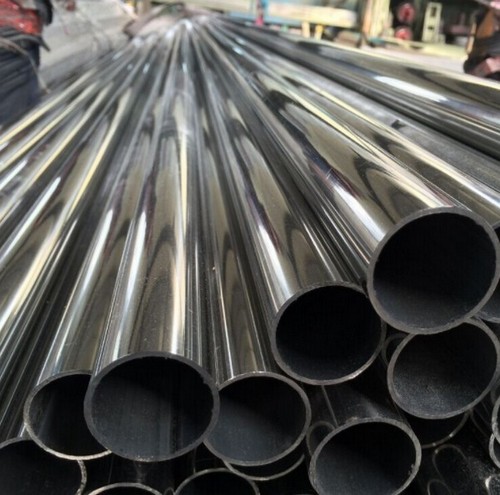

production workshop

production workshop

production workshop

production workshop

Hot sale product

| stainless steel pipe sizes | 6 stainless steel stove pipe |

| stainless steel exhaust pipes | stainless steel pipe fabrication |

| stainless steel pipe clamp | 3 4 stainless steel pipe |

| stainless steel screen pipe | 304 stainless steel pipe |

| stainless steel smoker pipe | 3in stainless steel pipe |

| 5 inch stainless steel exhaust pipe | 4 stainless steel pipe |

Application

Our steel products are mainly used in chemical industry, petrochemical industry, offshore, seawater pipeline, desalination plant, nuclear engineering, paper and pulp industry.

stainless steel pipe outlet

We are a well known worldwide supply and export stainless steel pipe in following countries:,Italy, Philippines, France,Ireland, Portugal, Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Libya, Romania, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Ghana, Slovakia, Germany, Saudi Arabia, Afghanistan, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece, Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus, Finland, Gabon, Iran, Canada, Argentina, Lebanon.

津ICP备14003658号-55

津ICP备14003658号-55