Carbon steel boiler tube description

Carbon steel boiler tube for high pressure is a seamless carbon steel boiler tube.Generally used for high pressure boiler (working pressure is generally not greater than 9.8Mpa, working temperature between 450℃-650℃) heating surface pipe, collection box, economizer, superheater, reheater, etc. (P<9.8MPa,450℃), It is often applied to seamless carbon steel tube with minimum wall thickness for high pressure boiler and superheater.

Carbon steel boiler tube chemical composition

Boiler tube standard | Grade | Chemical composition of carbon steel boiler tubes | |||||||||

C | Si | Mn | P | S | Cr | Mo | Cu | Ni | V> | ||

ASTM A192ASME SA192 | A192 | 0.06-0.18 | ≤0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 | / | / | / | / | / |

Carbon steel boiler tube mechanical property

strength of extension(MPa) | yield strength(MPa) | elongation( % ) | hardness |

≥325 | ≥180 | ≥35 | ≤77HRB |

Carbon steel boiler tube specification

Product Name | Carbon steel boiler tube |

Thickness | 0.5~75mm/custom |

Surface | Polishing,annealing,pickling,bright |

Technology | Cold/hot rolled |

Steel Grade | 10#-45#, A53-A369, Q195-Q345, ST35-ST52, Grade A, Grade B, Grade C,etc. |

Standard | ASTM A213,A312,ASTM A269,ASTM A778,ASTM A789,DIN 17456,DIN17457,DIN 17459,JIS G3459, JIS G3463,GOST9941,EN10216, BS3605,GB13296 |

Tolerance | a) Outer Diameter: +/- 0.5mm |

Test | Squash test, extended test, water pressure test, crystal rot test, heat |

Packing | Standard export packing |

Machining | Custom, kaiping, cutting, pattern |

Outer Diameter | 0 - 3048mm |

Length | 1 - 12m |

Carbon steel boiler tube derusting method

(1) Cleaning: the use of solvents, emulsions to clean the surface of high-pressure boiler steel pipe, in order to remove oil, grease, dust, lubricant and similar organic matter, but it can not remove the surface of high-pressure boiler steel pipe rust, oxide skin, welding, so in the anti-corrosion production only as an auxiliary means.

(2) Tool derusting: mainly use wire brush and other tools to polish the surface of high-pressure boiler steel pipe, which can remove loose or warped oxide skin, rust, welding slag and so on. Hand tools can reach Sa2 level, power tools can reach Sa3 level, if the surface of the high pressure boiler steel pipe attached to the solid oxide sheet, the tool rust removal effect is not ideal, can not reach the anticorrosive construction requirements of anchor grain depth

(3) pickling: Generally using chemical and electrolytic two methods to do pickling treatment, pipeline anticorrosion only chemical pickling, can remove oxide skin, rust, old coating, sometimes it can be used as a sand blast after rust removal reprocessing. Chemical cleaning can make the surface reach a certain degree of cleanliness and roughness, but its anchor lines are shallow and easy to pollute the environment.

(4) Spraying (throwing) jet rust removal: spraying (throwing) jet rust removal is driven by a high-power motor to spray (throwing) jet blade high-speed rotation, so that the steel sand, steel shot, iron wire section, minerals and other abrasive on the surface of the steel pipe under the action of centrifugal force spraying (throwing) jet treatment, not only can completely remove rust, oxides and dirt, And the steel tube of high pressure boiler can achieve the required uniform roughness under the action of abrasive fierce impact and friction force.

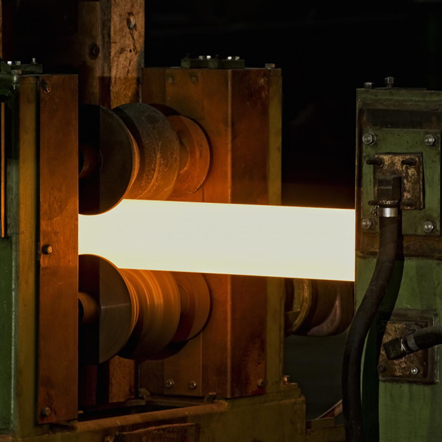

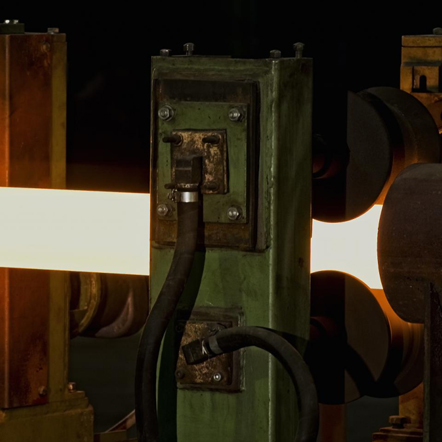

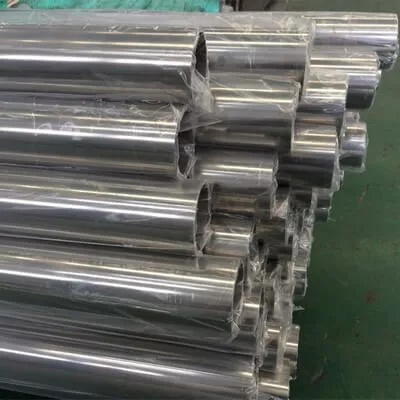

production workshop

production workshop

production workshop

production workshop

Hot sale product

| sa106c boiler steel pipe factory | seamless steel carbon boiler pipes |

| sa106c boiler steel pipe manufacturer | seamless steel carbon boiler pipes factory |

| sa106c boiler steel pipe suppliers | seamless steel carbon boiler pipes supplier |

| sa210c boiler steel pipe | stainless steel 304 boiler pipes |

| sa210c boiler steel pipe exporter | stainless steel boiler exhaust pipe |

| sa210c boiler steel pipe factory | stainless steel boiler pipe factories |

Application

Our steel products are mainly used in chemical industry, petrochemical industry, offshore, seawater pipeline, desalination plant, nuclear engineering, paper and pulp industry.

Exporting country

We are a well known worldwide supply and export Boiler steel pipe in following countries:,Italy, Philippines, France,Ireland, Portugal, Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Libya, Romania, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Ghana, Slovakia, Germany, Saudi Arabia, Afghanistan, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece, Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus, Finland, Gabon, Iran, Canada, Argentina, Lebanon.

津ICP备14003658号-55

津ICP备14003658号-55