nm400 wear-resistant steel plate description

nm400 wear-resistant steel plate advantage

NM400 wear-resistant plate is a high-strength wear-resistant steel plate, which has a high resistance to wear, Brinell hardness of 400 (HBW) is mainly in the need of wear-resistant occasions or parts to provide protection, so that the service life of the equipment is longer, reduce maintenance and shutdown, the corresponding reduction of capital investment.Wear-resistant steel plate has high wear resistance and good impact performance. It can be cut, bent, welded, etc. It can be connected with other structures by welding, plug welding, bolt connection, etc. It has the characteristics of saving time and convenient in the maintenance field

nm400 wear-resistant steel plate application

Widely used in metallurgy, coal, cement, electric power, glass, mining, building materials, brick and other industries.Compared with other materials, it has a high cost performance and has been favored by more and more industries and manufacturers.

nm400 wear-resistant steel plate Specification

Product Name | hot rolled wear steel ar400 ar500 nm400 nm500 wearing resistant steel plate | ||

Standard | AISI,ASTM, EN, BS, GB, DIN, JIS | ||

Materials | NM360,NM360L,NM400,NM400L,NM400A,NM450,NM450L,NM450A,NM500A.NM550,NM600. NR360,NR400,MITTA 400F,MITTA 450F,MITTA 500F DILLIDUR400,DILLIDUR500,DILLIDUR400V,DILLIDUR500V,DILLIDUR450V FORA400,FORA500,CREUSABRO4800,CREUSABRO8000 | ||

Inspection | ISO,BV,SGS,MTC | ||

Packing | Waterproof paper, and steel strip packed. | ||

Supply Ability | 250000 metric tons/Year | ||

MOQ | 5 metric ton,sample order accepted | ||

Shipment time | Within 7-10 workdays after receiving deposit or L/C | ||

Payments | T/T,LC | ||

Chemical Content | ||||||||

Steel/Grade | C | Si | Mn | P | S | AL | Cr+Ni+Mo | Nb+V+Ti |

NM360/AR360 | 0.10-0.30 | 0.20-0.40 | 1.00-2.00 | ≤0.015 | ≤0.003 | ≥0.20 | <0.6 |

Trace Amount |

NM400/AR400 | 0.10-0.40 | 0.20-0.40 | 1.00-2.00 | ≤0.015 | ≤0.003 | ≥0.20 | <0.9 | |

NM450/AR450 | 0.10-0.40 | 0.20-0.40 | 1.00-2.00 | ≤0.015 | ≤0.003 | ≥0.20 | <1.2 | |

NM500/AR500 | 0.10-0.40 | 0.20-0.45 | 1.00-2.00 | ≤0.015 | ≤0.003 | ≥0.20 | <1.5 | |

NM550/AR550 | 0.10-0.50 | 0.20-0.45 | 1.00-1.50 | ≤0.015 | ≤0.003 | ≥0.20 | <2.0 | |

NM600/AR600 | 0.10-0.50 | 0.20-0.45 | 1.00-1.50 | ≤0.015 | ≤0.003 | ≥0.20 | <2.5 | |

nm400 wear-resistant steel plate Mechanical properties

| Material | Thickness(mm) | Strength of extension | Elongation | Impact energy(vertical) | BH(Brinell Hardness) | |

| ºC | Akv/J | |||||

| NM400 | 6-80 | ≥1200 | ≥10 | -20 | ≥24 | 370-430 |

nm400 wear-resistant steel plate Chemical composition

| Brand | C | Si | Mn | P | S | Cr | Mo | Ni | B | CEV |

| NM400 | ≤0.24 | ≤0.50 | ≤1.6 | ≤0.025 | ≤0.015 | 0.4~0.8 | 0.2~0.5 | 0.2~0.5 | ≤0.005 |

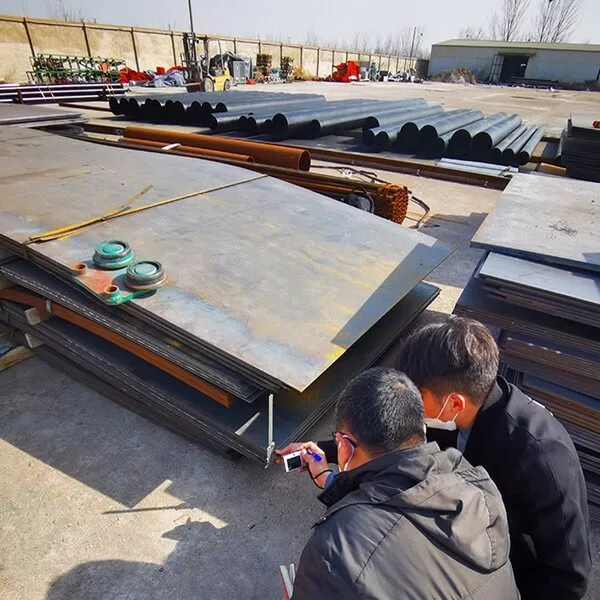

production workshop

production workshop

production workshop

production workshop

Hot Products

| 1025 carbon steel plate | 1060 carbon steel plates |

| 1030 carbon steel plate | 1070 high carbon steel plate |

| 1035 carbon steel plate | 1075 carbon steel plate |

| 1040 carbon steel plate | 1075 high carbon steel plate |

| 1045 carbon steel plate | 1080 carbon steel plate |

| 1049 carbon steel plates | 12 x1 8 carbon steel plate |

| 1055 carbon steel plate | 1215 carbon steel plate |

| 1060 carbon steel plate | 1ft by 1ft high carbon steel plate |

Application

Our steel products are mainly used in chemical industry, petrochemical industry, offshore, seawater pipeline, desalination plant, nuclear engineering, paper and pulp industry.

Export area

We are a well known worldwide supply and export nm400 wear-resistant steel plate in following countries:,Italy, Philippines, France,Ireland, Portugal, Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Libya, Romania, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Ghana, Slovakia, Germany, Saudi Arabia, Afghanistan, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece, Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus, Finland, Gabon, Iran, Canada, Argentina, Lebanon.

津ICP备14003658号-55

津ICP备14003658号-55